Wuxi Longchao Metal Products Co. Ltd was established in 2001 and is located in China's largest stainless steel production base - Jiangsu Province. Our company is an integrated company, gathering the stainless steel production, trade, processing, logistics and distribution. The main products include steel sheets, steel plates, steel coils, steel pipes, steel tubes, steel bars, steel circles, square steel, hexagonal bar, steel tube, steel pipe fittings, flanges, etc. And also we can produce according to the requirments of the costomer. The production capacity of our company is anout 250000 tons per year.

The total area of manufactory is about 60, 000square meters and it has its own stainless steel research and development department, production department and selling department.

Strict quality control system and perfect after-sales service system are always our top concern which can guarantee and track the quality of our products from raw materials procurement, production processes, finish products as well as after-sales service.

Products Description

1. Specifications about stainless steel sheet

| Commodity | Cold rolled & Hot rolled Stainless Steel Sheet |

| Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

| Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Thickness | 0.2mm-150mm |

| Width | 1000,1219,1250,1500mm, or as your requirements |

| Length | 2000,2438,2500,3000,6000mm, or as your requirements |

| Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

| Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

| Delivery time | 5-7 days after confirming the order |

| MOQ | 1 Ton |

| Advantages | Showing the splendor of your quality, wear-resistant as well , strong anti-corrosion and decorative effect, durable and beautiful in good taste. |

2. Chemical Composition about stainless steel sheet

| Grade and Main chemical composition% | |||||||||

| C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other | |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | 0.06 | 0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10.0 | 0.06 | 0.03 | 17-19 | - | 4.0-6.0 | N≤0.25 |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | - | 6.0-8.0 | - |

| 303 | ≤0.15 | ≤1.00 | ≤2.00 | 0.2 | ≥0.015 | 17-19 | ≤0.6 | 8.0-10.0 | - |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 8-10.5 | - |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 2-3 | 10-14 | - |

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | 0.04 | 0.03 | 16-18 | - | ≤0.6 | |

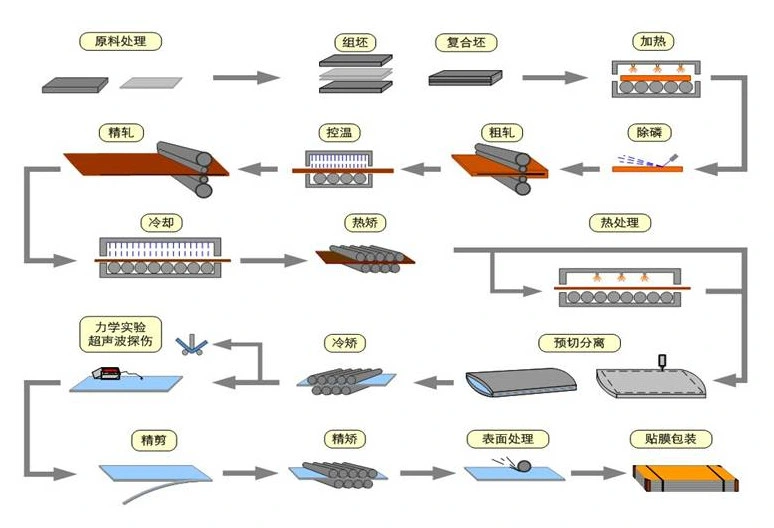

3. Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shift operation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealing and pickling by our experienced staff

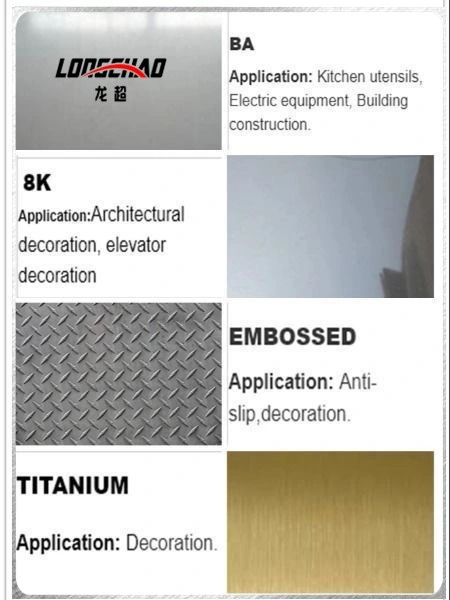

4.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Production Process

Production Workshop

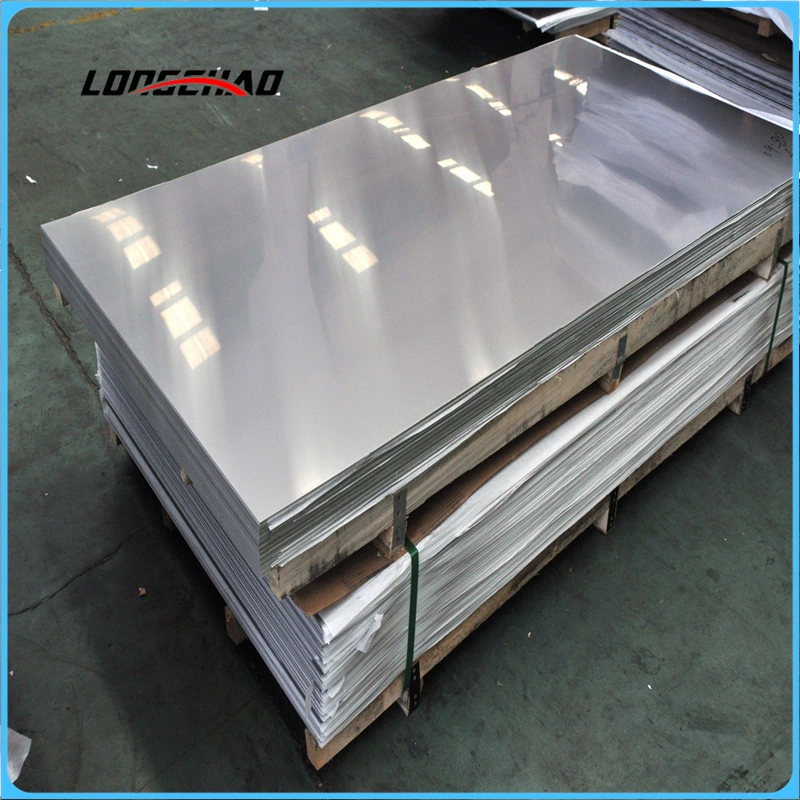

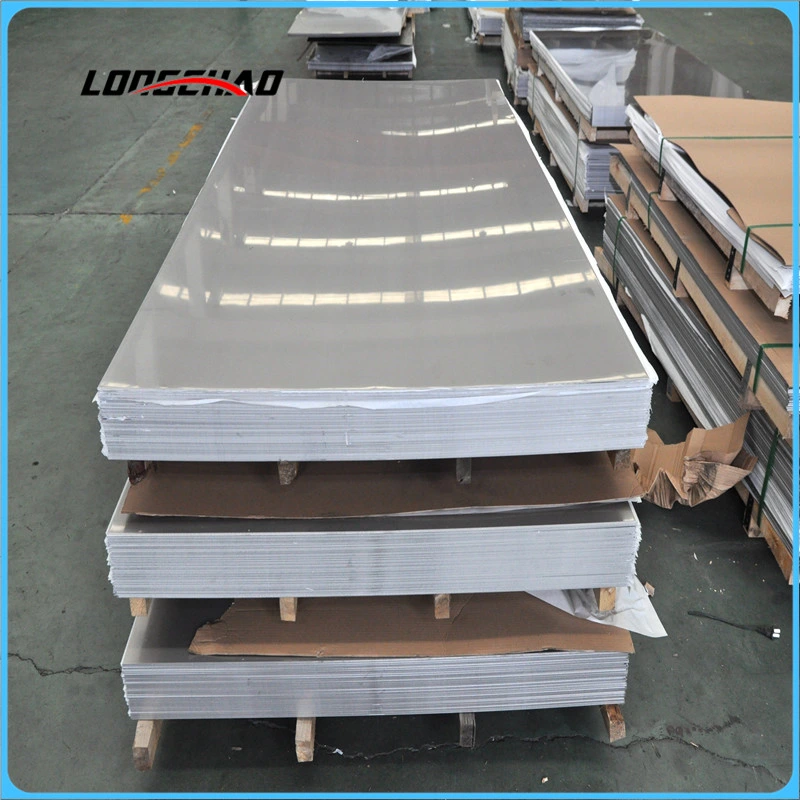

Product Show

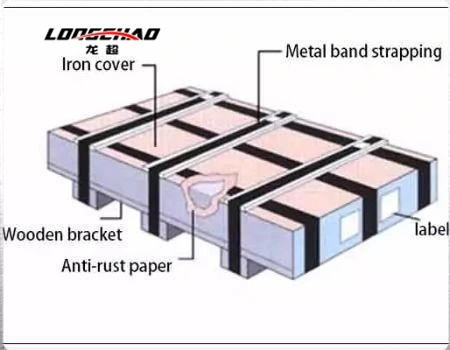

Packagement

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.

FAQ

Q: Can I get some samples free?

A: Free sample can be provided if you require to check the quality.

Q: How long will it take to execute my order?

A:Our normal lead time is 5-10 working days.,but we have many models in stock,We will let you know the estimated lead time after payment ASAP.

Q: Do you have inspection procedures for the products?

A:100% self-inspection before packing

Q: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

ADD:Room 660, Building B, No.168, Qian Gao Road, Liangxi District in Wuxi Jiangsu province

Q: What can you do for us?

A: We always shorten delivery time for our buyer.

We always package steel products well.

We always fix steel product in container well to make it safe arrive at destination port.

We always provide best and professional forward service and after sales service.

We can't promise price but quality! Trust is the basic of business. Wish to establish a long-term relationship with you!

If you are interested in my products, please feel free to contact me any time! Welcome to receive your inquiry!

Contact person: Amy Pei Tel: 086-15895365606